Key points of the article

- Araldite structural adhesives are an advanced solution for making strong, reliable and durable joints in technically demanding industries such as aerospace, automotive and energy.

- Proper application procedures to achieve effective bonding: from surface preparation to curing management.

- Adhesive bonding offers numerous advantages over traditional methods, including better stress distribution, increased stiffness, corrosion protection, and superior aesthetic finish.

- We also analyze the main design considerations to be taken into account, such as thermal and chemical resistance, curing times, and compatibility between materials.

Huntsman ‘s Aralditeindustrial adhesives are an advanced and reliable solution for making strong and durable structural joints. Due to their excellent adhesion to a wide range of materials, including metals, plastics, glass and rubber, they are successfully used in highly demanding industries such as:

- Aerospace

- Automotive

- Wind energy

- Railway

- Construction

- Medical Equipment

Innovation in materials and manufacturing processes has made the design of structural joints increasingly complex. In this context, Araldite adhesives offer an effective answer, enabling new engineering challenges to be met with high-performance and versatile solutions. Reliability, strength and ease of use are the main advantages that make them the ideal choice for designers and engineers looking for alternatives to mechanical assembly or welding.

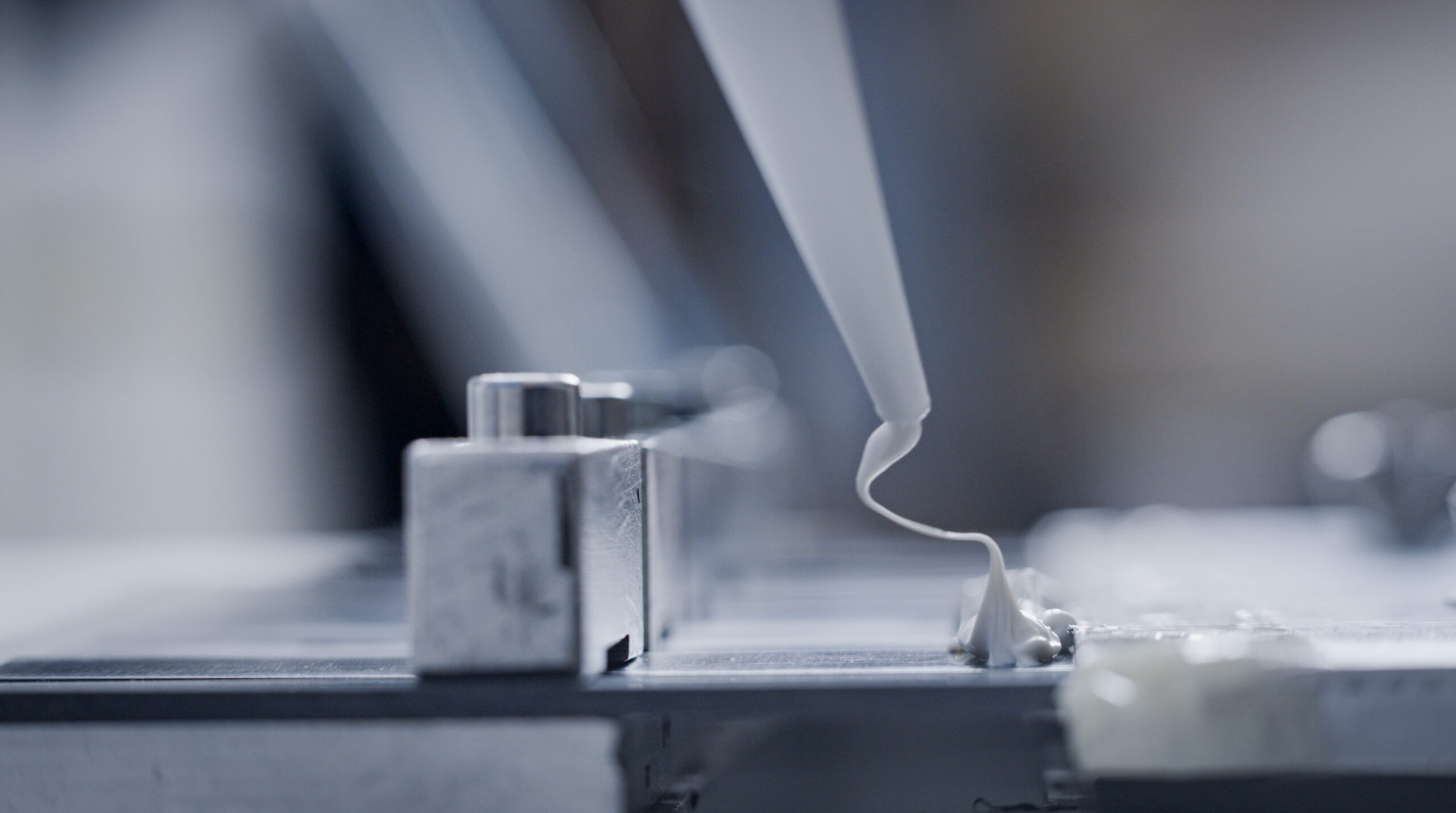

The procedures to be followed for perfect adhesive bonding

To achieve maximum performance, it is essential to follow precise application procedures and adhere to optimal curing conditions:

- The resin and curing component must be precisely measured in the correct ratio and mixed thoroughly.

- Joint surfaces should be degreased and, if necessary, pretreated.

- It is essential to adhere to minimum curing temperatures and times.

- Fasteners should be used to prevent movement of surfaces during curing.

- Although only light pressure is needed, this should be applied evenly over the entire bonding area. Excessive pressure may reduce the amount of adhesive in the various structural joints.

Advantages of adhesive bonding over other fixing methods

Adhesive bonding represents an innovative and versatile solution in industrial assembly, offering numerous advantages over traditional mechanical fastening methods or welding. Among the main benefits are:

- The reduction of stresses

- Increased structural rigidity

- A cleaner and more aesthetically pleasing design

- Less complexity in the production of components.

In addition to technical benefits, the use of adhesives has tangible economic benefits. Bonded jointdesign allows fordesign optimization, reducing the number of components and simplifying manufacturing processes. In addition, theabsence of mechanical fasteners allows for faster assembly, reduction of the overall weight of the structure, and longer product life.

Better stress distribution and increased strength

Unlike welding or mechanical fasteners, which concentrate stress at specific points, adhesive bonding distributes stresses over the entire bonded area. This feature improves fatigue resistance and extends the life of structural joints under prolonged loads, avoiding critical failure points.

Improved aesthetic appearance

The use of structural adhesives eliminates the need for visible fasteners such as screws or rivets, allowing for a cleaner, more uniform finish. In addition, theabsence of spotwelds prevents the formation of irregularities on the surface of the material.

Increased structural rigidity

Due to the continuity of the adhesive bond, bonded structures are generally stiffer than those assembled by traditional methods. If, on the other hand, you want to reduce the weight of the structure, you can decrease the thickness of the material without compromising its strength.

Adaptability to different materials

Structural adhesives make it possible to join materials with different physical properties, including metals, plastics, glass and composites. This allows innovative assemblies to be designed without the limitations imposed by compatibility in welding processes or mechanical fastening.

Protection against corrosion

The continuous adhesive bond acts as a protective barrier against external agents, preventinginfiltration of moisture or chemicals that could accelerate deterioration of the material. This aspect is particularly advantageous in environments with high exposure to weathering or in industries such as automotive and aerospace.

Advanced applications: electrical insulation and vibration damping

Some adhesives are formulated to offer additional properties, such as conduction orelectrical insulation, making them ideal for electronics and industrial equipment. In addition, vibration-damping characteristics allow for improved comfort and safety in structures under dynamic stress.

Adhesive bonding, therefore, not only simplifies and improves production processes but also offers structural and economic advantages, making it a strategic choice for a wide range of industrial applications.

Evaluation of bonding: limitations and design considerations

Although adhesive bonding offers many advantages over traditional fastening methods, it is essential to evaluate its limitations to ensure optimal performance and long service life. The strength of a bonded joint depends on multiple factors, including:

- operating temperature

- exposure to chemicals

- the curing times

- Proper surface preparation.

Thermal resistance

One of the critical aspects of structural bonding is thermal resistance. Adhesives, being polymeric materials, undergo changes in their mechanical properties as temperature changes. Asheat increases, their stiffness can decrease, moving from an elastic to a plastic state, compromising the bond strength of the joint. For this reason, it is essential to choose the type of adhesive according to the operating temperature range of the final component.

Chemical resistance

Chemical resistance plays a key role in the durability of bonding. The polymer structure of adhesives can be altered by solvents, oxidizing agents or other aggressive substances in the operating environment. Therefore, adhesive selection must take into account operating conditions, including chemical compatibility tests to ensure stable adhesion over time.

Hardening times

Curing time is another key element to consider. Unlike other immediate fastening methods, adhesives require some time to reach maximum bond strength. During this phase, the component must be held in place with special fasteners to avoid movement that could compromise the quality of the bond. In some cases, hybrid bonding, combining adhesives and mechanical fasteners, can be an effective solution to ensure immediate stability during curing.

Proper surface preparation

The quality of bonding also depends on the preparation of the surfaces. If joint surfaces are not properly degreased and treated, the adhesive may not adhere properly, compromising the strength of the joint. It is therefore essential to follow specific pretreatment procedures, such as solvent cleaning or sandblasting, to optimize adhesive wettability and maximize bond strength.

Discover the ideal products for industrial adhesive bonding processes

Our Araldite product range reflects all the features to make your adhesive and structural bonding operations more efficient and process-optimized. To learn more and ask for more information contact our Mascherpa experts, who will be at your disposal for clarification on the products and their practical use.